◇ Introduction ◇ Function◇ Parameter◇ Product order◇ Download◇ Related products

Introduction

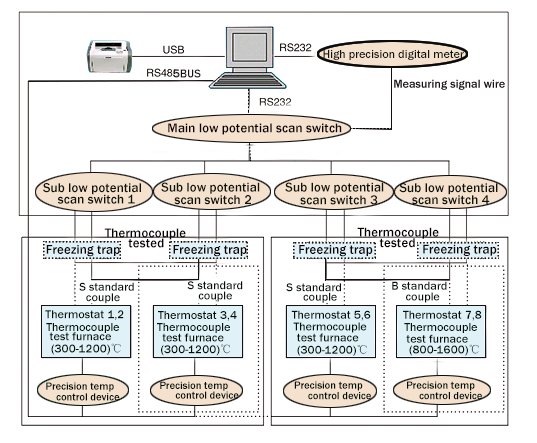

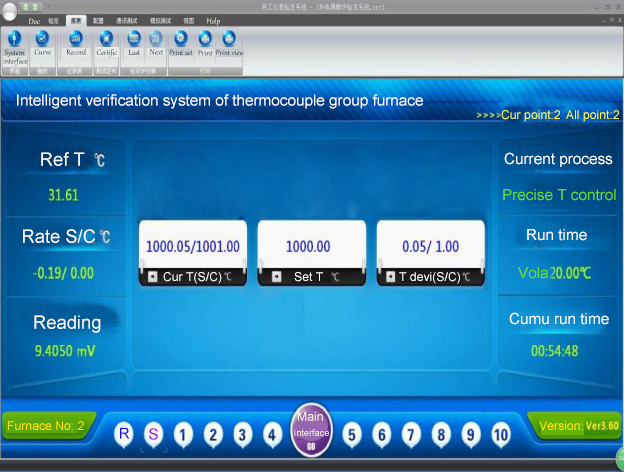

DTZ-02G automatic verification system for thermocouple(Group Furnace) and thermistor is used for automatic verification / calibration of various standard thermocouples, working thermocouples, industrial thermal resistance, can simultaneously control 1-10 verification furnaces, each verification furnace One to ten thermocouples can be verified at a time, which can meet the requirements of verifying large batches of thermocouples in a short time. The system adopts a number of technological innovations of the company, and its software and hardware are independently developed by the company and have completely independent intellectual property rights.

Technical Parameters

◇ Multi-channel scanning switch parasitic potential: ≤0.2μV

◇ Difference of data acquisition between channels: ≤0.5μV 1mΩ

◇ Measurement repeatability: ≤1.0μV 3mΩ

◇ Thermostatic performance of thermocouple verification furnace: constant temperature≤0.5 ℃ / 6min, measurement≤0.1 ℃ / min

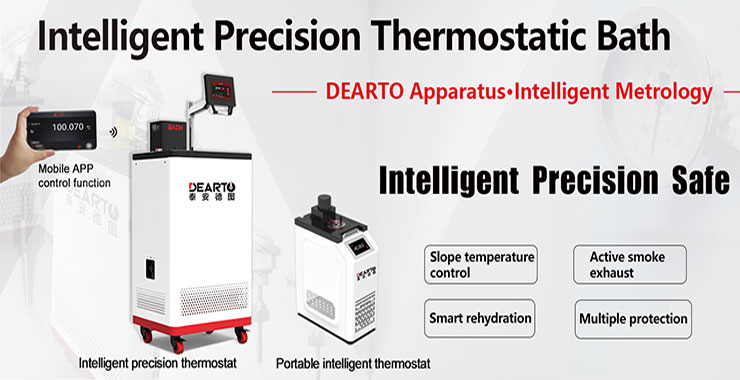

◇ Constant temperature performance of constant temperature oil and water bath: constant temperature≤0.02 ℃ / 10min, measurement≤0.01 ℃ / min

◇ Compensation range of thermocouple reference terminal: 0 ℃ -50 ℃ Resolution: 0.01 ℃

Function

1. The verification system can be used to verify / calibrate various working thermocouples such as B, S, K, N \ E, etc., which can be controlled simultaneously.

2. 10 thermocouple verification furnaces, each verification furnace can simultaneously verify 10 thermocouples with different index numbers at a time.

3. No manual intervention is required during the verification process. Realize the functions of automatic temperature control, automatic data detection, automatic data processing, generating various verification reports, storage and database management.

4. The temperature control system adopts imported intelligent PID regulator with RS485 communication function as the temperature controller. The advanced expert PID algorithm is adopted to effectively prevent overshoot during temperature control.

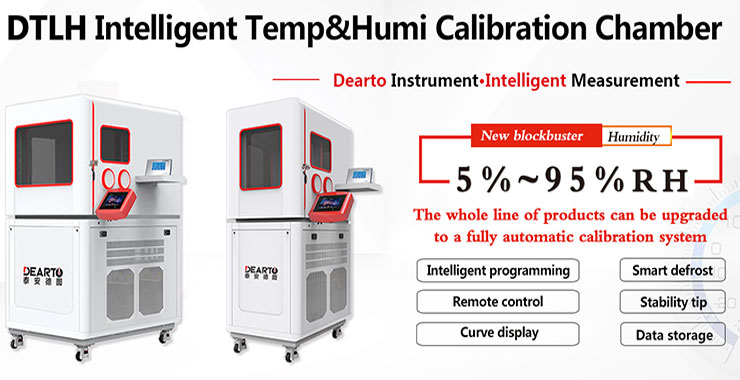

5. The thermocouple group furnace verification system software runs independently and is compatible with low-temperature constant temperature baths and constant temperature oil baths to achieve normal communication, control, and acquisition verification work.

6. The working thermocouple provides a variety of reference end processing methods: 0 ° C compensation or automatic room temperature compensation can be used.

7. The verification system can carry out verification of thermal resistance A, B and other levels (Pt10, Pt100, Pt_X, Cu50, Cu100, Cu_X), low temperature thermocouple, integrated temperature transmitter.

8. It can realize batch verification.

9. When the system verifies the thermal resistance and the thermocouple, they do not interfere with each other and can be used separately.

10. The mixed verification function can realize the mixed verification of base metal thermocouples with different index numbers in the same furnace.

11. ITS 90 international temperature scale conversion software can be provided: through mobile phone APP, universal thermocouple, industrial thermal resistance, standard platinum resistance, temperature transmitter can be used to convert the value of electricity and temperature; the PC can realize the conversion of temperature unit ; Conversion of working thermocouple (including WRe3 and WRe5) temperature value and electric potential value, and can calculate differential thermoelectric potential; conversion of industrial thermal resistance temperature value and resistance value, and can calculate differential thermal resistance; calculate standard couple according to standard certificate Potential value of 300-1300 degrees celsius and conversion of potential value and temperature value within the range; according to the standard certificate value to standard thermal resistance to obtain the temperature value from the resistance value or the resistance value from the temperature value; wet and dry bulb humidity conversion; heat transfer coefficient conversion ; Heat transfer rate conversion; power unit, pressure unit, diffusion coefficient, length unit, area unit, surface tension, speed unit, force unit, dynamic viscosity, kinematic viscosity, energy unit conversion.

12. The verification system meets the requirements of relevant regulations such as JJF1098-2003 "Calibration Specification for Thermocouple and Thermal Resistance Automatic Measurement System".

| Previous:DTZ-03G automatic simultaneous verification system for thermocouple and thermistor | next:Custom temperature and humidity verification/calibration chamber |

Tel

Tel

Product

Product

Contact

Contact

Home

Home