◇ Introduction ◇ Function◇ Parameter◇ Product order◇ Download◇ Related products

Introduction

DT Pro Wireless Temperature / Humidity / Pressure Verification System can be widely used in equipment verification and environmental monitoring in pharmaceutical, food, biological, chemical and other industries. Compared with the traditional wired verification system, the probe can be conveniently and quickly arranged, and the detection point is physical constraints greatly improve verification efficiency.

Function

The system consists of a wireless recorder (temperature, humidity, pressure), a data reading workstation, and wireless verification software.

The temperature recorder can effectively store 16000 pieces of data, and the temperature measurement accuracy is 0.1 ℃, which fully meets the needs of equipment and process verification in food and drug production enterprises and the verification needs in the fields of bioengineering, medical and transportation. The recorder uses replaceable batteries, with large power, low power consumption and long battery life. Adopt high pressure and waterproof design, can be used continuously for a long time in high pressure and high humidity environment.

The data reading workstation is divided into a single-hole workstation and a 10-hole workstation. The universal USB serial port is used to connect to the computer, and data communication can be carried out conveniently, efficiently and safely.

The software realizes data collection, data analysis and report generation, meets FDA 21 CFR Part 11, and supports electronic signature of documents. Support custom stages and verify each stage to generate stage verification report.

Features:

◇ Switch between Chinese and English versions at will;

◇ Comply with FDA 21CFRPart 11 regulations;

◇ With data audit tracking function, with three levels of authority (freely assignable authority);

◇ It has data statistical analysis functions, including large and small values, average value, span, temperature difference at the same time, F0 value test, etc., and can be freely selected according to needs.

Application scenarios:

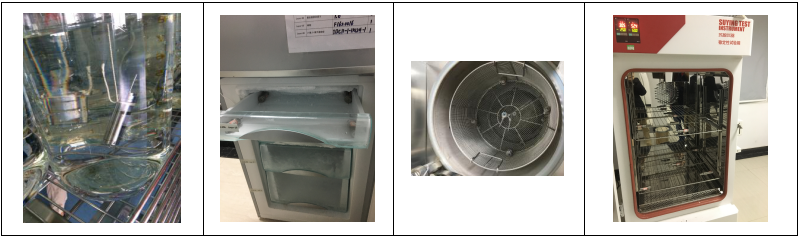

The system can be applied to GMP pharmaceutical industry, GSP industry, biological industry, medical industry, food industry, transportation industry.

| GMP | Steam sterilizer verification / water bath sterilizer verification, rubber plug washer verification / aluminum lid washer verification, freeze dryer verification / cryogenic refrigerator verification, constant temperature and humidity chamber verification / stability incubator verification |

| GSP | Cold storage verification / refrigerated truck verification, refrigerator / incubator verification, cool storage / normal temperature storage verification |

| Biological | Stirred fermentation tank verification, culture tank verification, process development data |

| Food | Pasteurization verification, sterilization tunnel verification, rotary freezer verification, blast freezer verification, cold room verification |

| Transport | Cold chain process tracking, cabin temperature detection |

| Medical | High temperature sterilization testing, steam sterilization testing, medical supplies testing |

Implemented procedures and specifications:

| Serial number | Regulation code | Procedure name |

| 1 | GBT 30690-2014 | The sterilization effect monitoring method and evaluation requirements of small pressure steam sterilizer |

| 2 | PDA TR1-2007 | Damp heat sterilization verification |

| 3 | JJF 1366-2012 | "Calibration Regulations for Temperature Data Collector" |

| 4 | JJF 1101-2003 | "Code for Calibration of Temperature and Humidity of Environmental Test Equipment" |

| Related regulations | "Pharmaceutical Production Quality Management Standards" (revised in 2015) "Guidelines for Pharmaceutical Production Verification" (2003 edition) FDA 21CFRPart11 Clause EN285-2006 (German Standard) EN554: 1994 (German Standard) HTM2010 (British Standard) | |

Technical Parameters

| Temperature Verifier | Temperature and humidity tester | Pressure Verifier | ||

| Model | TDLA | TDLC(Flexible probe) | MDLA | PDLA |

| Operating temperature | -50 ~ 150 ° C (expandable to 400?C with heat insulation box) | -50 ~ 150 ° C (expandable to 400?C with heat insulation box) | -40~125°C | -40~140°C |

| Range | -50~150°C | -50~150°C | 0~100%RH | 0~100psi 0~6.894Bar (Absolute pressure) |

| Resolution | 0.01°C | 0.01°C | 0.01°C | 0.008psi; |

| 0.01%RH | 0.55mBar | |||

| Accuracy | ±0.1°C | ±0.1°C | ±0.2°C | ±2.5% Full scale |

| ±2%RH | ||||

| Sensor | Pt100 Class 1/3 DIN | Pt100 Class 1/3 DIN | Temperature: Pt100 | Strain |

| Humidity: capacitive | ||||

| Capacity (recording points) | 64,000 | 64,000 | 8,000 | 8,000 |

| Record frequency | 1 second to 18 hours | 1 second to 18 hours | 1 second to 18 hours | 1 second to 18 hours |

| Battery Life | 36 months | 36 months | 12 months | 12 months |

| Communication method | RS 485 Contact | RS 485 Contact | RS 485 Contact | RS 485 Contact |

| Previous:DTSW-1 Stick Type Standard Digital Thermometer (Industrial Temperature Calibration) | next:Custom temperature and humidity verification/calibration chamber |

Tel

Tel

Product

Product

Contact

Contact

Home

Home