When calibrating temperature should I use liquid calibration bath or dry block calibrator?Where is the difference?Although both calibrators are used as stable temperature sources for the calibration of temperature sensors, different uncertainties can be achieved. However, which one to use depends on the environment, industry, and application.

Liquid calibration bath

For a work area of uniform temperature, Dearto recommend the use of Liquid calibration bath. The Liquid calibration bath uses liquid as the heat-conducting medium, Through the control system and the stirring or jet device, the temperature in the internal working area is kept uniform, and the fluctuation is only 0.0007℃/10min. Depending on the liquid used for heating and cooling and the thermostat, users typically use several Liquid calibration baths with different temperature ranges. Therefore, the sensor can be calibrated at multiple temperatures.

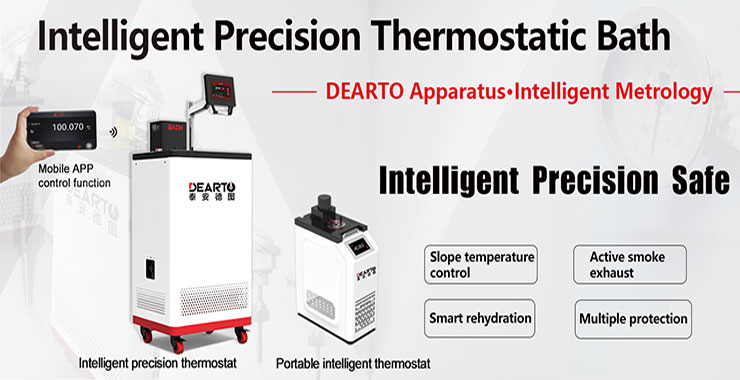

There are two types of Liquid calibration bath, portable calibration bath, and precision calibration bath for large, permanently installed laboratories. Because the temperature environment they generate is stable and uniform, you can achieve the lowest calibration uncertainties. Another advantage is that probe rods of all sizes and shapes can be calibrated by simply immersing them in the working area of the Liquid calibration bath.

Due to the medium of the Liquid calibration bath , it is also limited in use. Since the calibrated object needs to be immersed in oil or other liquids, the Liquid calibration bath cannot be used in sterile requirements (the environment must be free of pollution). For example, a probe used in the food industry to measure the temperature of milk could contaminate the product if it was dipped in oil for calibration.

Dry block calibrators

Dry block calibratorss are commonly used in the aseptic industry to calibrate temperature probes. Due to the portable nature of the dry block calibrators, it can be used for on-site temperature calibration, and can also be used for fixed use in the laboratory. The dry block calibrators is equipped with a uniform temperature block, which can make the probe better test the temperature in the dry well. To calibrate, insert the test object into the drilled hole in the calibration block. Here, care must be taken to secure the probe rod. In order to avoid air flow around the measured temperature probe, the maximum clearance can only be a few millimeters. Ambient air can affect the measured value and thus the calibration result. If the built-in thermometer is used, the dry block calibrators is heated or cooled to the set temperature, and then the temperature value measured by the probe is measured using the built-in thermometer for verification.

The dry block calibrators is chosen, first of all, because of the portable calibration feature, the calibration object does not have to be in contact with any liquid; another advantage is that the probe rod will not come into contact with other substances that may be harmful to the final product. If multiple probes are being calibrated at the same time, the mutual interference of the tips will be a challenge and the number of calibrations will be limited. Sometimes the user must also purchase multiple equalization blocks - to accommodate various probe rods. Most blocks are made of brass or aluminum, and ceramic blocks are also used to ensure more stable temperatures when calibrating at very high temperatures.

Liquid calibration bath and dry block calibrators are performed by measuring a temperature point within the temperature range of the sensor and comparing the result to a reference meter; both can also be calibrated using a fixed point, such as the triple point of water. This is based on the International Temperature Scale of 1990 (ITS-90). With fixed-point calibration, laboratories can use pre-defined fixed points to measure high-precision thermometers such as standard platinum resistance thermometers.

Tel

Tel

Product

Product

Contact

Contact

Home

Home