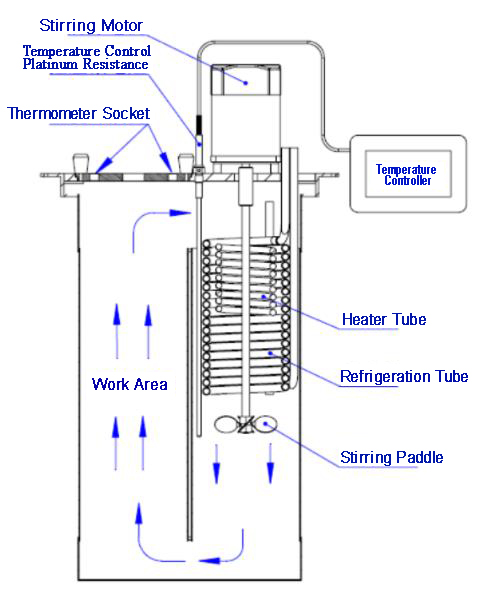

The calibration bath is a kind of equipment used for laboratory verification and calibration. Generally, the liquid is used as the heat transfer medium. Through the action of the temperature control system and the stirring or jet device, the set temperature or the set temperature change rate is reached, and its internal temperature is maintained. The temperature in the working area is uniform and stable. The liquid calibration bath is mainly suitable for biopharmaceutical, petrochemical, aerospace, food and other industries. It is mainly used as constant temperature equipment for verification and calibration of various temperature probes and temperature sensors.

People often ask, How does a calibration bath work? Is it the same as other metrology calibration steps? Let's introduce these contents today? At the same time, you can click on the text below to learn about the relevant content.

Liquid Calibration bath Structural Drawing

What is a temperature calibration bath?

What is a liquid calibration bath?

What is the FOB price of liquid calibration bath?

What standard does the liquid calibration bath perform?

How to calibrate bath temperature?

Liquid Calibration Bath Recommendations for Laboratory Use.

How does a calibration bath work? Operation steps of constant temperature bath instrument

1. Selection of liquid medium (silicon oil, water, antifreeze, absolute ethanol, etc.)

2. Add liquid medium into the calibration bath, and the liquid level of the liquid medium should not be lower than 20mm of the workbench.

a. When the working temperature is lower than 5°C, the liquid medium is generally antifreeze and absolute ethanol.

b. When the working temperature is between 5°C and 80°C, the liquid medium is generally pure water.

c. When the working temperature is 80°C-90°C, the liquid medium generally adopts a mixture of water and oil.

d. When the working temperature is above 95°C, the liquid medium is generally grade A silicone oil, and the viscosity of the silicone oil is less than 50.

3. Connection of circulation pump:

a. The connection of the internal circulation pump: connect the liquid outlet pipe with the liquid inlet pipe hose (a hose is provided with the machine).

b. The external circulation pump is connected to the external circulation, and the liquid outlet pipe is connected to the hose at the entrance of the container outside the bath.

A liquid tube is connected to the outlet of the container outside the bath.

4. Plug in the power, turn on the "power" switch, and turn on the "cycle" switch.

The above are the calibration steps of opening the calibration bath. Friends who need it may wish to contact.

Dearto's calibration bath adopts touch screen control and operation, a fully intelligent human-machine interface, making the operation more convenient, simple and practical. The structure adopts double-chamber side stirring technology, and through intelligent PID adjustment, the constant temperature bath can achieve an ideal uniform temperature field, which meets various low-temperature thermocouples, industrial thermal resistance, pressure thermometers, bimetal thermometers, and glass liquid thermometers. Verification/calibration of temperature sensors.

Functional advantages:

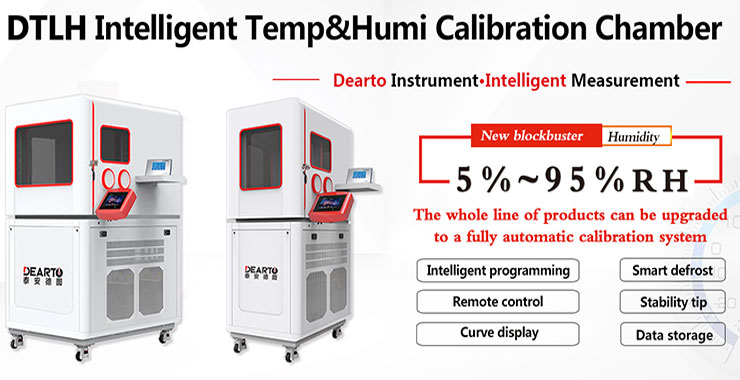

The temperature control rate is adjustable, and the heating rate can be set freely. Set the heating rate according to the actual verification or calibration, and heat up at a uniform speed to meet the verification/calibration of various temperature switches.

Real-time curve display, automatic calculation of volatility. Multi-touch can zoom and pan freely, and the volatility can customize the time period. stable duration.

Composite heat insulation design, more effectively block thermal bridges. Multi-layer composite heat insulation structure to ensure better temperature field stability and fluctuation

Dual sensor overheat protection, over temperature automatically cut off the power

Independent overheating monitoring hardware, double safety protection of software and hardware

It has an active smoke exhaust system to create a healthy working environment. Compatible structural design, flexible for various smoke exhaust scenarios

Support USB, WIFI, WLAN, serial port communication function

7. Intelligent automatic rehydration. Real-time monitoring by multiple liquid level sensors, intelligent automatic rehydration to prevent dry burning. Oil bath level alarm.

8. Ergonomic design, the temperature control screen is installed with a three-axis mechanical cantilever, and the angle and length can be adjusted at will, which is convenient for operation.

| Previous:Temperature and humidity calibration equipment | next:News | Metrology Industry Branding Event~ 2024 Guangzhou International Measurement and Testing Technology and Equipment Exhibition |

Tel

Tel

Product

Product

Contact

Contact

Home

Home