◇ Introduction ◇ Function◇ Parameter◇ Product order◇ Download◇ Related products

Product Overview:

DTZ-01AG Standard type Thermocouple Verification System is mainly used for automatic verification / calibration of various standard thermocouples. Through hardware design adjustment and software architecture upgrading, the system completes the deep optimization of the communication mechanism of the underlying equipment. The verification furnace can verify 1-10 thermocouples at a time.The system adopts a number of technological innovation achievements of the company, and its software and hardware are independently developed by our company and have fully independent intellectual property rights.

Product characteristics:

1. This thermocouple verification system can be used for the automatic verification / calibration of the standard thermocouples / precious metal thermocouples with different scale numbers of S, R and B.

2. During the verification process, manual intervention is unnecessary.Realize the complete automation to control temperature, data detection, data processing, generate various verification reports, storage and database management in the verification process.

3. The temperature control system adopts the imported intelligent PID regulator with RS485 communication function as the temperature controller.Advanced expert PID algorithm is adopted to effectively prevent the overshoot in the temperature control process.

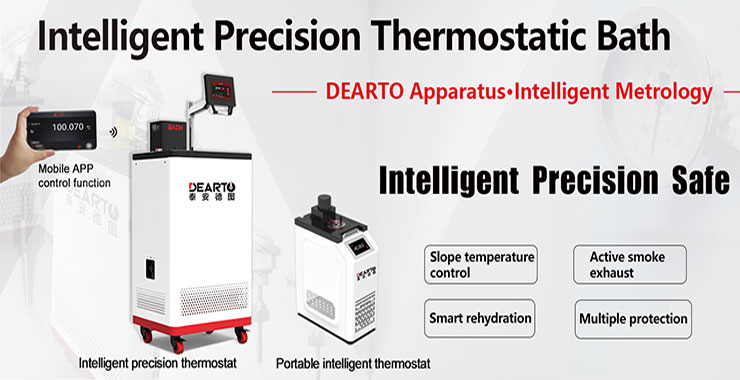

4. The software can operate independently, and can be compatible with cryotemperature bath and thermostatic oil bath, and thermocouples for different scale numbers. Normal verification of communication, control and collection can be realized in the verification process.

5. The system has mixed verification function, which can realize hybrid verification of different scale number standard thermocouples in the same furnace.

6. ITS 90 international temperature standard conversion software can be provided: through mobile APP, universal thermocouple, industrial thermoelectric resistance, standard platinum resistance, and temperature transmitter can be convenient to achieve power value and temperature conversion; The PC terminal can achieve the conversion of the temperature unit; Conversion of operating thermocouple temperature and potential values (including WRe3 and WRe5), And the differential thermal potential can be calculated; Conversion of industrial thermal resistance temperature value and resistance value, And the differential thermal power resistance can be calculated; Calculate the potential value of the standard even 300-1300 degrees C and the conversion of the potential value and the temperature value within the range according to the standard certificate; Seek the temperature value or the resistance value according to the standard certificate value; Dry and wet ball humidity conversion; Conversion of the heat transfer coefficient; Heat transfer speed conversion; Conversion of power units, pressure units, diffusion coefficient, length units, area units, surface tension, speed units, force units, power viscosity, motion viscosity, and energy units.

7. The verification system shall meet the requirements of JJF1098-2003 Calibration Code for Thermocouple and Automatic Thermal Resistance Measurement System and other relevant codes and specifications.

| Previous:DTSW-2 Stick Type Industrial Grade Precision Digital Thermometer | next:Custom temperature and humidity verification/calibration chamber |

Tel

Tel

Product

Product

Contact

Contact

Home

Home